Sign up to receive event and technology updates. Manual methods also require many experts in a non-collaborative workflow, can result in improper installation and drive a variety of costly manufacturing changes. Integration of mechanical, software and electronic systems technologies for vehicle systems. Straightforwardly design, simulate, analyse and off-line programme multi-device robotic and automated manufacturing processes. Event 04 juin France 3D Print Quality drives Chinese automaker; on route to creating a world-famous name Tecnomatix software helps Chery diagnose and reduce design quality defects, achieving significant savings for each problem found prior to manufacturing En savoir plus See all Success Stories. Remove barriers and grow while maintaining your bottom line.

| Uploader: | Kazilkis |

| Date Added: | 5 May 2008 |

| File Size: | 20.64 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 53813 |

| Price: | Free* [*Free Regsitration Required] |

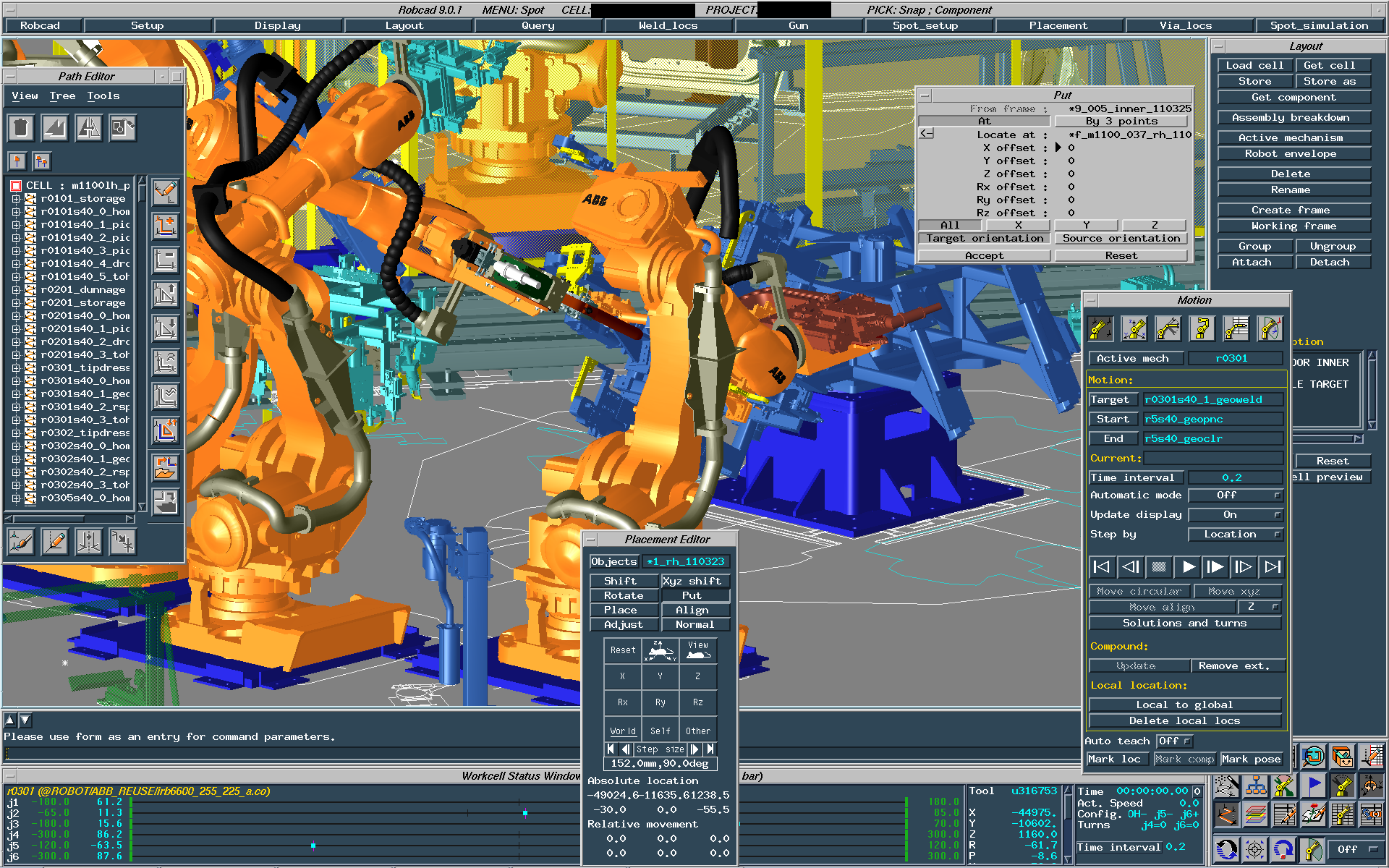

Tecnomatix Robcad is a workcell simulation tool that provides you the ability to develop, simulate, optimize, validate, and off-line program multi-device robotic and automated manufacturing processes, all in the context of configured product and resource data.

Tecnomatix RobCAD

Contact Change Region Rechercher Basculer la navigation. Tecnomatix Robcad allows you to visualise and virtually confirm the practicality of your automation concepts, instead of dealing in guesswork or uncertainties. Increase manufacturing quality, accuracy and profitability Reduce labour hours and process engineering lead time Optimise development and capital investment Enable better use of production equipment Reduce production costs Shorten ramp-up time through validated processes Accelerate time-to-market.

Key Capabilities and Benefits Interoperability with mainstream CAD systems 3D layout definition of automation workcells Accurate simulation and synchronization of multiple robots and mechanisms Extensive library of standard robot models and robot controller configurations Automation tools for robot placement, equipment selection, path planning and optimization, program generation and collision detection.

Interested in this solution? Business improvement Teamcenter Polarion.

Looking for technical support? Integration of mechanical, software and electronic systems technologies for vehicle systems. Manufacturing NX Manufacturing Tecnomatix.

The Robcad platform helps to optimise processes and calculate cycle times. Digital Manufacturing Environment For Robotic Workcell Verification And Off-Line Programming As industries are pressed to meet timing and flexibility within manufacturing systems, there is need to make sure all aspects of the system have been proven-out before costly purchasing and installation decisions take place.

Straightforwardly design, simulate, analyse and off-line tecjomatix multi-device robotic and automated manufacturing processes.

Visibility, compliance and accountability for insurance and financial industries. Barre de recherche mobile Effacer tecnomatkx champ de recherche Rechercher. Manual methods also require many experts in a non-collaborative workflow, can result in improper installation and drive a variety of costly manufacturing changes.

In general, these methods cannot account for all the checks necessary to create efficient manufacturing systems.

Siemens PLM Software, a leader in media and telecommunications software, delivers digital solutions for cutting-edge technology supporting complex products in a rapidly changing market. Capabilities Interoperability with major CAD systems 3D layout definition of workcells Accurate simulation and synchronization of several robots and mechanisms Over 50 standard robot models and robot controller configurations Automation tools for robot placement, equipment selection, path planning and optimization, program generation tecnpmatix collision detection Benefits Reductions in process engineering lead time Increase manufacturing quality, accuracy and profitability Accurate robot programs downloaded to the shop floor Increased production equipment utilization for maximum return Detect simulation problems at early stages of planning Validate and optimize welding programs to corporate specifications Cost reduction reflected from process development to implementation.

Robcad has a powerful selection of process-specific applications, including spot welding, arc welding, laser- and water-jet cutting, drilling and riveting, and human operations. Supply chain collaboration in design, construction, maintenance and retirement of mission-critical assets. ROBCAD Robcad is a workcell design and simulation tool that allows you to develop, simulate, optimize, validate, and offline program multi-device robotic and automated roobcad processes Siemens PLM Software also offers Process Simulate Robotics and Robot Expert product for robotics simulation and offline programming.

Quality drives Chinese automaker; on route to creating a world-famous name Tecnomatix software helps Chery diagnose and reduce design quality defects, achieving significant savings for each problem found robcac to manufacturing En savoir plus See all Success Stories. Older, manual methods are no longer sufficient to develop these complex manufacturing systems. These full-action mockups of complete manufacturing cells and systems within a 3D environment provide a platform tecnomaix optimize processes and calculate cycle times throughout the various stages of the development timeline, from concept through implementation.

Siemens Tecnomatix Digital Manufacturing Robcad Software - Delhi NCR Gurgaon

Faster time to market, fewer errors for Software Development. Event 04 juin France. Benefits Reduced process engineering lead time Increased manufacturing quality, accuracy and profitability Accurate robot programs downloaded to the shop floor Increased production equipment utilization for maximum return Problems detected and solved with simulation teccnomatix early stages of planning Validated and optimized welding programs based on corporate specifications Reduced cost reflected from process development through to implementation.

As a scalable solution, Robcad fully integrates core technologies and a powerful set of process-specific applications that addresses a wide range of processes, including spot welding, tecnomatux welding, laser and water-jet cutting, drilling, riveting and painting.

These promote knowledge re-use and save you time. These full-action mockups of complete manufacturing cells and systems within a 3D environment provide a platform to optimize processes and calculate cycle times throughout the various stages of the development timeline, from concept through implementation.

Tecnomatix Robcad Overview Tecnomatix Robcad allows you to visualise and virtually confirm the practicality of your automation concepts, instead of dealing in guesswork or uncertainties. Or simply wish to get our expert opinion on a product?

Tecnomatix

Twitter Facebook Linkedin E-mail Google. Robcad fully integrates core technologies and a powerful set of process-specific applications addressing a roncad range of manufacturing processes including spot welding, arc welding, laser and water-jet cutting, painting and spraying, and material handling.

We supply trusted Siemens PLM technology for: Tecnomatix software helps Chery diagnose and reduce design quality defects, achieving significant savings for each problem found prior to manufacturing.

No comments:

Post a Comment